Quality Control & Inspection Systems

Process-driven quality management ensures consistent performance and full traceability from raw materials to finished products. ISO 9001:2015 and IATF 16949 certified operations.

Quality System Overview

Our quality management system is built on a process-based approach, covering all stages of production from material receipt through final inspection and shipment. Each process stage includes defined inspection points, acceptance criteria, and documentation requirements.

Quality records are maintained for traceability, and non-conforming products are identified, segregated, and handled through our corrective action process. Regular internal audits and management reviews ensure continuous improvement.

Quality Workflow

- 1.Material Receipt: Incoming materials are verified against purchase specifications and material certificates.

- 2.Incoming Inspection (IQC): Dimensional checks, material verification, and certificate review.

- 3.Production: Process parameters monitored and controlled per work instructions.

- 4.In-Process Inspection (IPQC): First-piece approval, dimensional checks, and process monitoring at defined intervals.

- 5.Coating/Plating: Pre-treatment verification, coating thickness measurement, and visual inspection.

- 6.Final Inspection (FQC/OQC): Comprehensive dimensional, visual, and functional checks before packaging.

- 7.Documentation: Inspection records, test certificates, and lot traceability documents prepared.

- 8.Release: Quality approval and shipment authorization.

Incoming Inspection (IQC)

All incoming raw materials and components undergo inspection upon receipt. This includes verification of material certificates, dimensional checks, and visual inspection for surface defects.

Material Verification

- • Material certificate review (chemical composition)

- • Mill certificate verification

- • Material grade confirmation

- • Lot/batch number recording

Dimensional Checks

- • Wire diameter verification (micrometers)

- • Material length/dimension checks

- • Surface condition inspection

- • Visual defect identification

In-Process Inspection (IPQC)

Continuous monitoring during production ensures process stability and early detection of deviations. First-piece approval is required before batch production begins.

First-Piece Approval

- • Complete dimensional inspection

- • Thread verification (GO/NO-GO gauges)

- • Visual inspection

- • Documentation and approval sign-off

Process Monitoring

- • Sampling inspection at defined intervals

- • Dimensional checks (calipers, micrometers)

- • Process parameter verification

- • Tool wear monitoring

Final Inspection (FQC / OQC)

Comprehensive inspection before packaging and shipment includes dimensional verification, functional testing, coating quality assessment, and visual inspection for defects.

Dimensional Inspection

- • Thread gauges (GO/NO-GO for internal/external threads)

- • Calipers and micrometers for critical dimensions

- • Head height, diameter, and length measurements

- • Thread pitch and major/minor diameter checks

Visual & Functional Checks

- • Surface finish and appearance

- • Coating uniformity and defects

- • Burr and sharp edge inspection

- • Functional assembly testing (where applicable)

Testing & Measurement Capabilities

Dimensional Measurement

- • Digital calipers (0.01mm resolution)

- • Micrometers (0.001mm resolution)

- • Thread gauges (GO/NO-GO sets per ISO/ANSI standards)

- • Height gauges and depth micrometers

Mechanical Testing

- • Hardness testing (Rockwell, Vickers where applicable)

- • Tensile strength testing (for material verification)

- • Torque testing (for threaded fasteners)

- • Torque-tension relationship verification

Coating Analysis

- • Coating thickness measurement (eddy current, XRF)

- • Coating composition verification

- • Adhesion testing (cross-cut, bend tests)

- • Visual inspection for plating defects

Material Verification

- • Material certificate review

- • Chemical composition verification (via certificates)

- • Material grade confirmation

- • Traceability documentation

Coating Verification

Coating quality is verified through thickness measurement, adhesion testing, and corrosion resistance testing. Performance depends on coating system, substrate preparation, and application parameters.

Thickness Measurement

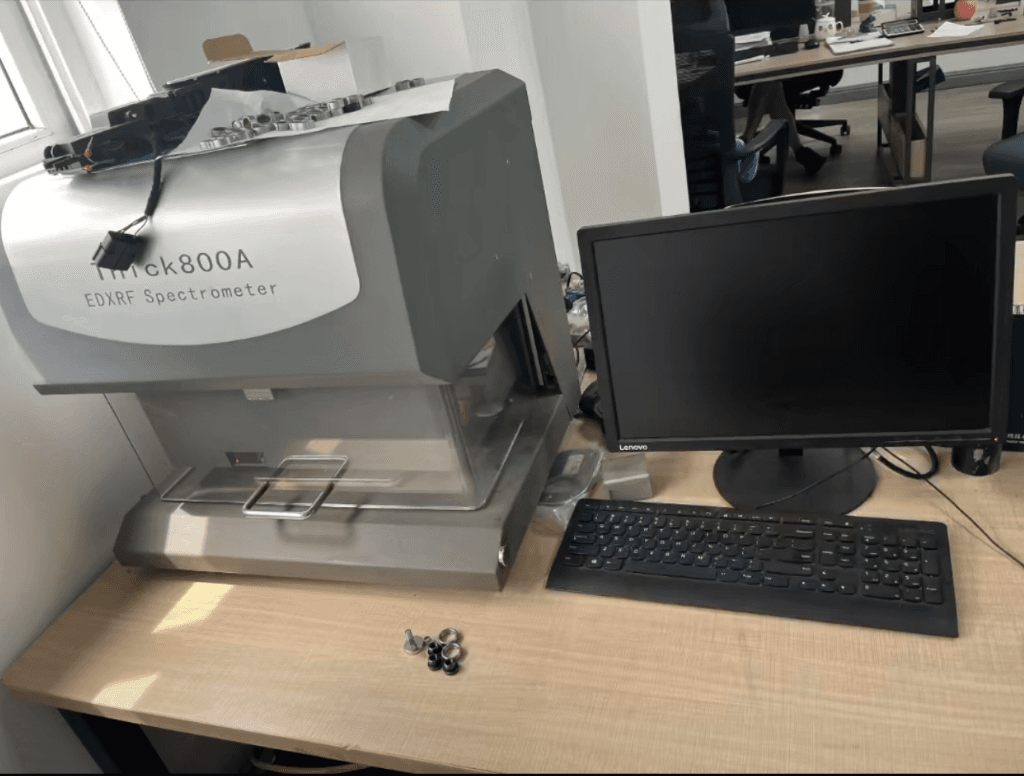

Coating thickness is measured using eddy current or X-ray fluorescence (XRF) methods. Our EDXRF spectrometer enables precise measurement of coating thickness and elemental composition. Target thickness varies by coating type and customer specification.

- • Multiple point measurement per part

- • Uniformity verification

- • Minimum thickness compliance

Adhesion Testing

Coating adhesion is verified through cross-cut tests, bend tests, or impact tests depending on coating type and specification requirements.

- • Cross-cut adhesion test (per ISO 2409)

- • Bend test for ductility

- • Visual inspection for delamination

Corrosion Resistance Testing

Neutral Salt Spray (NSS) testing is conducted per ASTM B117 or ISO 9227 standards. Test duration and acceptance criteria depend on coating system and customer specification. Typical test durations range from 240 to 1000+ hours depending on coating type and performance requirements.

- • Neutral Salt Spray Test (NSS) per ASTM B117 / ISO 9227

- • Test duration specified per coating system and customer requirements

- • Visual evaluation for white rust, red rust, and coating degradation

- • Test reports available upon request

Traceability & Documentation

Full traceability is maintained from raw material receipt through final shipment. Lot and batch numbers are recorded and linked to inspection records and test certificates.

Lot/Batch Traceability

- • Material lot numbers recorded at receipt

- • Production batch numbers assigned

- • Coating batch tracking

- • Shipment lot identification

Inspection Records

- • IQC inspection reports

- • IPQC monitoring records

- • FQC inspection certificates

- • Test data and measurement records

Certificates & Documentation

- • Material certificates (CoC/CoA)

- • Inspection certificates

- • Test reports (salt spray, coating thickness)

- • Packing lists with lot identification

Document Retention

- • Quality records maintained per retention policy

- • Electronic and physical record storage

- • Traceability available for customer inquiries

- • Documented procedures for record management

Continuous Improvement & Corrective Actions

Non-conformances are identified, investigated, and addressed through our Corrective and Preventive Action (CAPA) process. Root cause analysis is performed, and actions are implemented to prevent recurrence.

CAPA Process

- • Non-conformance identification and documentation

- • Root cause analysis

- • Corrective action implementation

- • Effectiveness verification

- • Preventive action planning

Continuous Improvement

- • Internal quality audits

- • Management review meetings

- • Process improvement initiatives

- • Customer feedback integration

- • Training and competency development

What Buyers Can Request

We support buyer requirements for quality verification and documentation. The following can be provided upon request:

Samples & Pre-Production

- • Pre-production samples for approval

- • First-article inspection reports

- • Sample inspection certificates

Production Documentation

- • Inspection reports (IQC, IPQC, FQC)

- • Test certificates (dimensional, coating, salt spray)

- • Material certificates (CoC/CoA)

- • Lot traceability documentation

Quality Packages

- • PPAP-like documentation packages (upon request)

- • Process capability studies

- • Quality plan documentation

Custom Requirements

- • Custom inspection protocols

- • Third-party inspection arrangements

- • Special test requirements

Note: Please specify your documentation and sample requirements during quotation or order placement. Additional documentation may incur additional charges and lead time. Contact us to discuss your specific quality assurance needs.