Zinc-Nickel Fasteners

720-1000+ Hours Salt Spray Protection

Superior corrosion resistance for automotive, EV, and industrial applications where reliability and durability matter.

What is Zinc-Nickel Plating

Alloy Composition

Zinc-nickel plating is an electroplated alloy coating containing approximately 10-15% nickel by weight, with the balance being zinc. The coating is applied through electrodeposition processes similar to standard zinc plating, but with modified bath chemistry to achieve the desired nickel content.

Enhanced Protection

The nickel content significantly improves electrochemical properties. Unlike pure zinc coatings, zinc-nickel coatings offer both barrier protection and enhanced corrosion resistance through the formation of more stable corrosion products. (Learn more about how nickel coatings protect fasteners) Learn why automotive OEMs prefer zinc-nickel coating for fasteners.

Plating Process

Surface preparation → Electrodeposition in zinc-nickel electrolyte bath → Trivalent chromium passivation (Cr3+) for enhanced corrosion resistance and uniform appearance.

Coating Thickness

Typical thickness: 8-15 microns. Excellent adhesion to steel substrates while maintaining dimensional tolerances critical for threaded fasteners.

Key Performance Characteristics

Corrosion Resistance

Zinc-nickel plated fasteners demonstrate significantly improved corrosion resistance compared to standard zinc plating. The alloy composition creates a more stable protective layer that resists degradation in salt, moisture, and chemical environments.

- •Typical salt spray performance: 720-1000+ hours (Neutral Salt Spray Test)

- •Superior resistance to red rust formation

- •Maintains protection in high-humidity environments

- •Compatible with trivalent chromium passivation for enhanced performance

Heat Resistance

Zinc-nickel coatings maintain protective properties at elevated temperatures where standard zinc plating may degrade. This characteristic is particularly important for automotive underhood applications and components exposed to thermal cycling.

- •Stable performance up to 200-250°C

- •Resistance to thermal degradation and oxidation

- •Suitable for applications with temperature cycling

- •Maintains coating integrity under thermal stress

Uniform Coating on Threads

The electroplating process ensures uniform coating distribution across all fastener surfaces, including internal and external threads. This uniformity is critical for maintaining thread tolerances and ensuring consistent corrosion protection.

- •Consistent coating thickness on thread flanks and roots

- •Maintains thread fit and dimensional tolerances

- •No buildup or bridging in thread areas

- •Compatible with standard thread gauging requirements

Salt Spray Performance

Neutral Salt Spray Test (NSS)

Salt spray testing is the standard method for evaluating corrosion resistance. The NSS test exposes specimens to a continuous salt fog environment (5% sodium chloride solution at 35°C) to simulate accelerated corrosion conditions.

Performance Comparison

ASTM B117

Standard Practice for Operating Salt Spray (Fog) Apparatus. Our testing procedures follow ASTM B117 to ensure consistent, reproducible results.

ISO 9227

International standard for salt spray tests. Ensures compatibility with global quality requirements and facilitates international trade.

Comparison: Zinc-Nickel vs Standard Zinc Plating

| Characteristic | Standard Zinc Plating | Zinc-Nickel Plating |

|---|---|---|

| Salt Spray Performance | 240-480 hours (NSS) | 720-1000+ hours (NSS) |

| Coating Composition | Pure zinc (99%+ Zn) | Zinc-nickel alloy (10-15% Ni) |

| Heat Resistance | Up to ~150°C | Up to 200-250°C |

| Corrosion Mechanism | Primarily sacrificial protection | Barrier + enhanced corrosion resistance |

| Cost | Lower cost | Higher cost (premium solution) |

| Typical Applications | Indoor applications, mild outdoor environments | Automotive, EV, harsh industrial environments |

Selection Guidance: Standard zinc plating is appropriate for applications with minimal exposure to corrosive environments or where cost optimization is prioritized. Zinc-nickel plating should be specified when extended service life, superior corrosion resistance, or elevated temperature performance is required. The decision should be based on application requirements, environmental conditions, and total cost of ownership considerations. For applications requiring wear resistance and dimensional stability alongside moderate corrosion protection, nickel-plated fasteners may provide an alternative solution.

Typical Applications

Automotive Applications

Zinc-nickel plated fasteners are widely used in automotive underbody components, chassis assemblies, and engine compartments where exposure to road salt, moisture, and temperature cycling requires enhanced corrosion protection.

- • Underbody structural components

- • Chassis and suspension fasteners

- • Engine compartment assemblies

- • Brake system components

EV Components

Electric vehicle battery enclosures and power systems require fasteners that maintain integrity under extended exposure to moisture, temperature cycling, and potential electrolyte exposure. Zinc-nickel plating provides the necessary corrosion resistance for these critical applications.

- • Battery enclosure assemblies

- • Rivet nuts for battery modules

- • Power distribution components

- • Thermal management systems

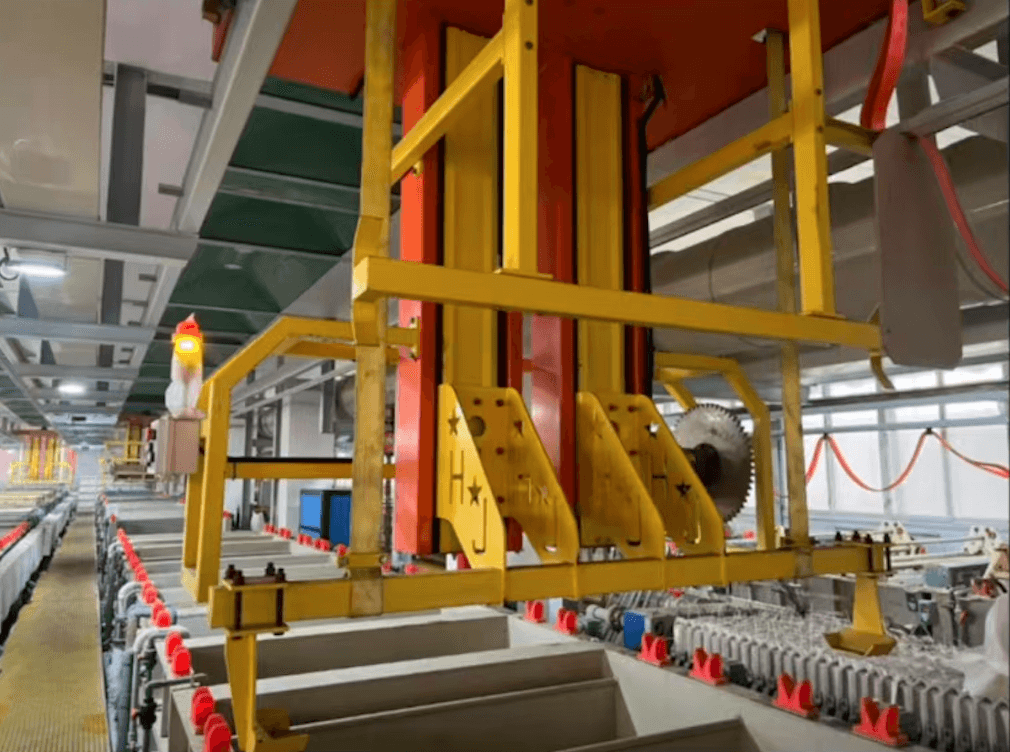

Industrial Equipment

Manufacturing equipment, outdoor machinery, and industrial enclosures benefit from zinc-nickel plated fasteners to reduce maintenance frequency and extend service life in harsh operating environments.

- • Outdoor equipment enclosures

- • Material handling systems

- • Process equipment assemblies

- • Industrial machinery fasteners

Energy Storage Systems

Battery storage containers and energy storage systems installed outdoors require fasteners with superior corrosion resistance to maintain structural integrity over extended service periods.

- • Battery storage enclosures

- • Power conversion systems

- • Outdoor installation hardware

Marine & Coastal Applications

High-salt environments require maximum corrosion resistance. Zinc-nickel coatings provide superior performance compared to standard zinc plating in marine and coastal applications.

- • Marine equipment assemblies

- • Coastal infrastructure

- • Offshore equipment

Aerospace & Defense

Critical applications requiring extended service life and reliable corrosion protection may specify zinc-nickel plating for enhanced performance in demanding operational environments.

- • Ground support equipment

- • Vehicle assemblies

- • Equipment enclosures

Design & Specification Considerations

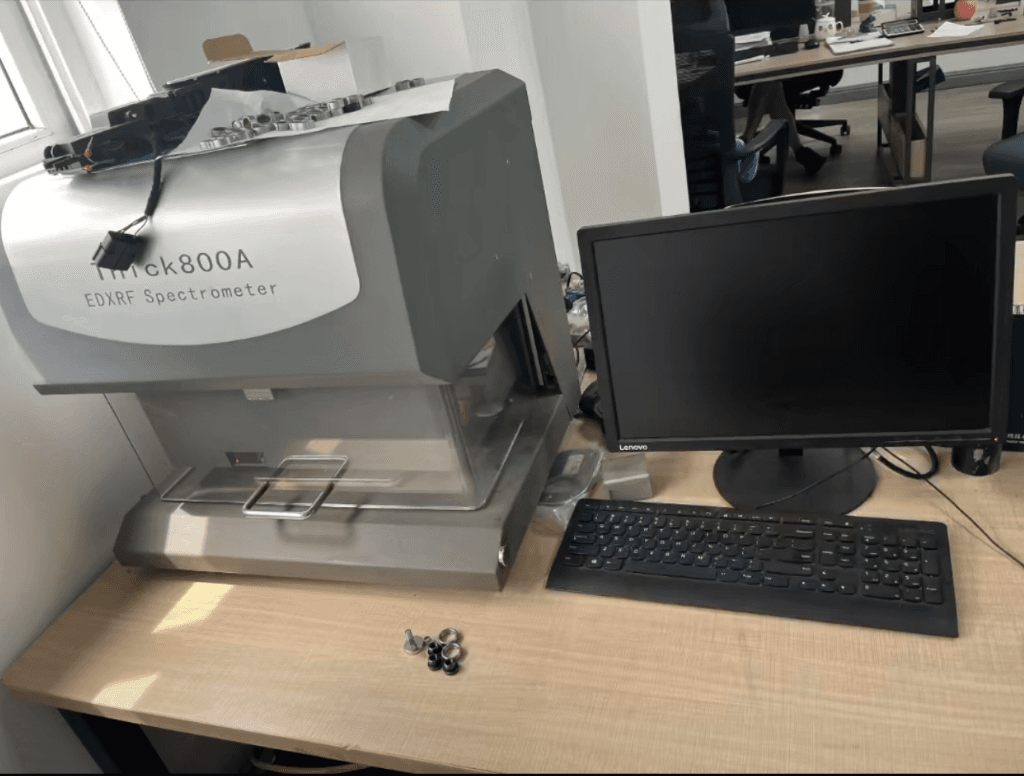

📏Coating Thickness

Typical thickness: 8-15 microns. Thicker coatings provide improved corrosion resistance but may affect thread tolerances. Specification should balance protection with dimensional constraints.

Measured using XRF (X-ray fluorescence) or eddy current methods. Test certificates available upon request.

⚙️Thread Tolerances

Maintains thread fit within standard tolerances. Process controlled to prevent buildup or bridging. Thread fit verification available for critical applications.

🔧Base Material Compatibility

Compatible with carbon steel, alloy steel, and stainless steel. Lower hydrogen embrittlement risk. Post-plating baking available for high-strength applications.

✨Passivation Treatment

Trivalent chromium passivation (Cr3+) enhances corrosion resistance by 20-30%. Environmentally compliant, RoHS compliant for international markets.

📋Specification Standards

ASTM B841, ISO 19598, and customer-specific requirements. Include coating thickness, salt spray targets, and passivation requirements in specifications.

For specification-based corrosion resistance requirements, please contact us to discuss application details. Contact us or email for technical support.

Technical Consultation

For specific zinc-nickel plating requirements, salt spray performance targets, or application-specific questions, our engineering team can provide technical support and recommendations.