Sealed Fastener Solutions

Engineered fastener systems designed to prevent moisture ingress and protect against internal corrosion in industrial equipment, electrical enclosures, and outdoor applications.

Sealed fasteners create a barrier that prevents water, dust, and contaminants from entering the joint, protecting both the fastener and the assembly from environmental degradation.

What Problems Sealed Fasteners Solve

Standard fasteners create pathways for environmental contaminants to enter assemblies. Sealed fasteners address two critical failure modes:

Moisture Ingress

Water and humidity can enter through fastener holes, threads, and gaps between components. Once inside, moisture creates an environment for corrosion, electrical failures, and material degradation.

- •Prevents water entry through fastener installation points

- •Blocks condensation and humidity from entering enclosures

- •Protects sensitive components from water damage

- •Maintains enclosure integrity in wet or humid environments

Corrosion from Inside the Joint

Once moisture enters a joint, it becomes trapped in crevices and gaps. This creates localized corrosion cells that attack the fastener and surrounding materials from the inside, often going undetected until failure occurs.

- •Eliminates trapped moisture in fastener joints

- •Prevents crevice corrosion in tight spaces

- •Reduces galvanic corrosion between dissimilar materials

- •Extends service life by protecting internal surfaces

Why Standard Fasteners Fall Short

Open-end fasteners create direct pathways for environmental contaminants. Even with external coatings, moisture can enter through the fastener bore, threads, or gaps between components. Once inside, trapped moisture accelerates corrosion and can cause premature failure.

Sealed fasteners address this by creating a physical barrier that prevents entry at the source, protecting both the fastener and the assembly from internal degradation.

Sealed Fastener Design Overview

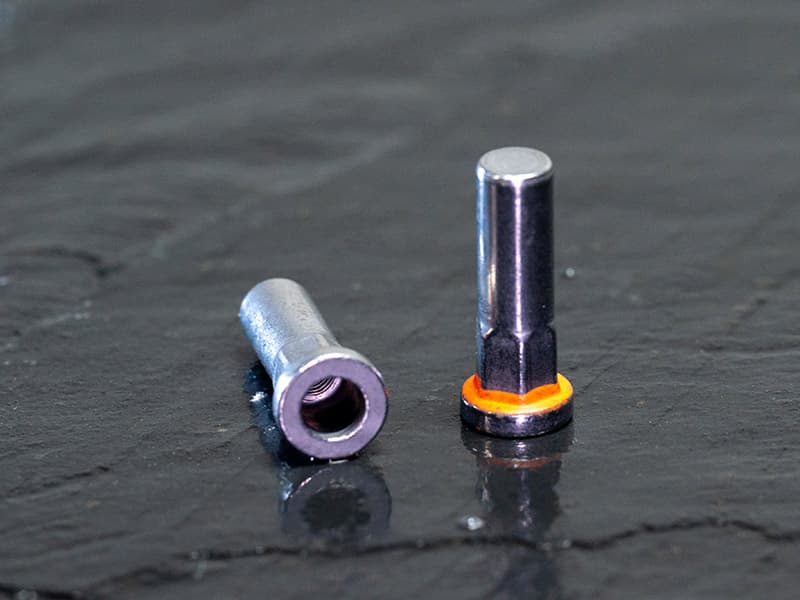

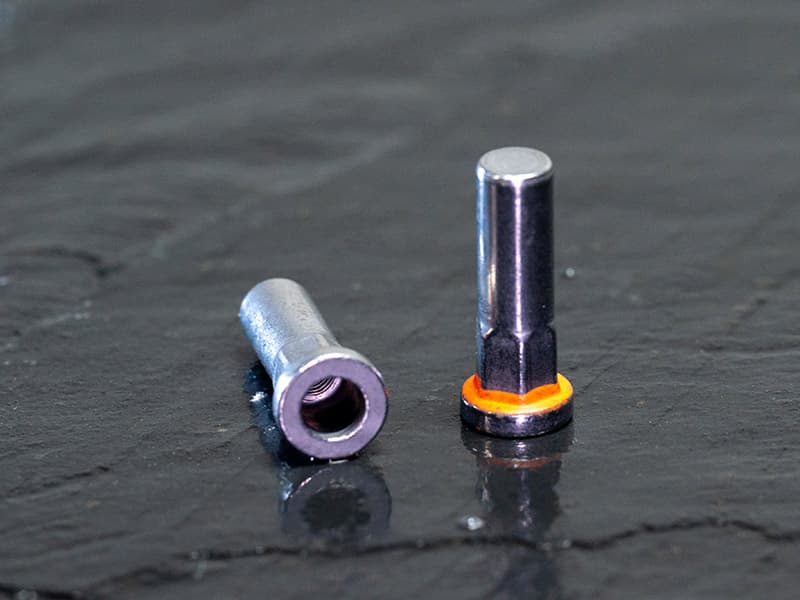

Closed-End Rivet Nut

Sealed bottom prevents moisture ingress

Sealed Fastener

Environmental protection for critical applications

Waterproof Design

Ideal for outdoor and harsh environments

Closed-End Rivet Nuts

Closed-end rivet nuts feature a sealed bottom that prevents passage of fluids, gases, and contaminants through the fastener bore. The closed end creates a barrier that blocks entry from one side of the assembly.

- •Sealed bottom: Prevents through-hole passage of moisture and contaminants

- •Thread protection: Internal threads remain protected from environmental exposure

- •Installation compatibility: Standard installation tools and processes apply

- •Material options: Available in carbon steel, stainless steel, and aluminum

Closed-end rivet nuts are ideal for applications where one side of the assembly must remain sealed, such as electrical enclosures, outdoor equipment housings, and fluid containment systems.

Sealing Principles

Effective sealing relies on creating a continuous barrier that prevents fluid and gas passage. Sealing effectiveness depends on material selection, design geometry, and installation quality.

- •Geometric sealing: Closed-end design creates a physical barrier preventing through-hole passage

- •Compression sealing: Proper installation creates compression between fastener and substrate, sealing gaps

- •Material compatibility: Sealing materials must resist environmental exposure and maintain integrity over time

- •Installation quality: Correct installation torque and technique ensure effective sealing

Note: Sealing performance depends on proper installation, substrate preparation, and environmental conditions. For applications requiring specific ingress protection ratings, consult with engineering teams to validate design suitability.

Design Considerations

Material Selection

- • Carbon steel with protective coatings for cost-effective solutions

- • Stainless steel for enhanced corrosion resistance

- • Aluminum for lightweight applications

- • Material choice affects sealing integrity and corrosion resistance

Installation Requirements

- • Proper hole preparation ensures effective sealing

- • Correct installation torque maintains compression seal

- • Substrate material and thickness affect sealing performance

- • Follow manufacturer installation guidelines for optimal results

Coating Compatibility with Sealed Designs

Sealed fasteners benefit from protective coatings that enhance corrosion resistance on exposed surfaces. Coating selection must consider both external protection and compatibility with sealing function.

Zinc-Nickel Coating

Zinc-nickel plating provides excellent corrosion protection for sealed fasteners in harsh environments. The coating protects exposed surfaces while maintaining sealing integrity.

- •720-1000+ hours salt spray protection on external surfaces

- •Coating does not interfere with sealing function

- •Compatible with trivalent chromium passivation

- •Recommended for outdoor and harsh environment applications

Zinc Coating

Standard zinc plating offers cost-effective corrosion protection for sealed fasteners in moderate environments. Suitable for indoor applications and mild outdoor conditions.

- •240-480 hours salt spray protection

- •Maintains sealing integrity with proper installation

- •Cost-effective for high-volume applications

- •Suitable for controlled indoor environments

Coating and Sealing Synergy

Protective coatings enhance sealed fastener performance by providing corrosion resistance on exposed surfaces. The combination of geometric sealing (closed-end design) and surface protection (coating) creates a comprehensive defense against environmental degradation.

- •Coating protects external surfaces from atmospheric corrosion

- •Sealed design prevents internal contamination and corrosion

- •Together, they provide comprehensive protection for critical applications

- •Coating thickness and uniformity are verified to ensure performance

Typical Applications

Electrical Enclosures

Electrical enclosures require protection against moisture ingress to prevent short circuits, corrosion, and equipment failure. Sealed fasteners prevent water entry through mounting points and access panels.

- •Control panels and junction boxes

- •Outdoor electrical equipment housings

- •Industrial automation enclosures

- •EV battery enclosure assemblies

Sealed fasteners protect sensitive electrical components from moisture-related failures and extend equipment service life.

Outdoor Equipment

Outdoor equipment faces continuous exposure to rain, humidity, temperature cycling, and environmental contaminants. Sealed fasteners prevent moisture entry and internal corrosion.

- •Outdoor machinery and equipment housings

- •Weather-resistant enclosures and cabinets

- •Solar panel mounting systems

- •Outdoor lighting fixtures and housings

Protection against moisture ingress is critical for maintaining equipment reliability in outdoor environments.

Industrial Equipment Enclosures

Manufacturing equipment, control systems, and industrial machinery require protection from factory environments that may include moisture, dust, and chemical exposure.

- •Machine tool enclosures

- •Process control cabinets

- •Industrial automation panels

Energy Storage Systems

Battery enclosures and energy storage systems require protection against moisture ingress to prevent electrical failures and corrosion in critical power systems.

- •Battery enclosure assemblies

- •Energy storage container systems

- •Power distribution enclosures

Selection Guidance for Sealed Fasteners

Selecting the appropriate sealed fastener requires evaluating environmental conditions, application requirements, and performance expectations. Consider the following factors:

1. Environmental Exposure

- •Indoor vs. outdoor: Outdoor applications require enhanced corrosion protection through coating selection

- •Moisture level: High humidity or direct water exposure requires sealed fasteners with appropriate coating

- •Temperature range: Consider thermal cycling effects on sealing materials and coatings

- •Chemical exposure: Evaluate compatibility with any chemicals or cleaning agents

2. Application Requirements

- •Sealing direction: Determine which side of the assembly requires sealing (closed-end design blocks one side)

- •Access requirements: Consider whether internal access through the fastener is needed

- •Mechanical loads: Ensure fastener strength meets application requirements

- •Installation method: Verify compatibility with available installation tools and processes

3. Material and Coating Selection

- •Base material: Carbon steel with coating for cost-effectiveness, stainless steel for enhanced corrosion resistance

- •Coating type: Zinc-nickel for harsh environments (720+ hours NSS), zinc for moderate conditions (240-480 hours NSS)

- •Substrate compatibility: Consider galvanic corrosion potential with assembly materials

- •Service life: Match coating performance to expected service life requirements

4. Installation Considerations

- •Hole preparation: Proper hole size and surface preparation ensure effective sealing

- •Installation torque: Follow manufacturer specifications to achieve proper compression seal

- •Substrate thickness: Verify compatibility with material thickness range

- •Quality verification: Inspect installation to confirm sealing effectiveness

Recommendation Process

For optimal fastener selection, provide the following information to your supplier:

- • Application description and environmental conditions

- • Technical drawings showing fastener locations and requirements

- • Substrate material and thickness

- • Expected service life and performance requirements

- • Installation method and tool availability

- • Any specific standards or certifications required

Find Your Sealed Fastener Solution

Share your application requirements, environmental conditions, and technical drawings. Our engineering team will recommend the optimal sealed fastener solution, including material selection, coating specification, and installation guidance.